The ThermoProfilScanner can be used to record welding irregularities from the temperature field of the welding seam that is solidifying but still glowing. Since the characteristics of the temperature field and the seam quality are directly correlated, seam irregularities such as weld penetration, offset, holes, etc.) can certainly be detected. ThermoProfilScanner is a part of the WeldQAS monitoring system.

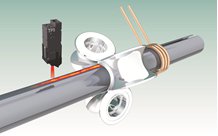

ThermoProfilScanner is an optical thermal field measuring device that records the temperatures on a line up to 400 times per second. The patented design is characterised by the thermal field camera, has a glassless construction and is suitable for permanent use near welding processes. A slot (18*1 mm) is used for measurements; this slot closes automatically when the shielding gas is not supplied. Owing to these prerequisites, it is possible to conduct an applied thermography test for the cooling welding seam.

ThermoProfilScanner has become especially important for welding method (high frequency induction, TIG, plasma, laser) used in seamless pipe production; it has replaced eddy current testing to a large extent.

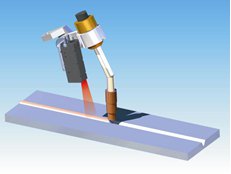

This system opens up new avenues of detecting welding irregularities even in case of non-continuous production processes. It detects welding irregularities immediately and allows a weld penetration check which surpasses the visual inspection of seam surfaces (e.g. laser scanning).

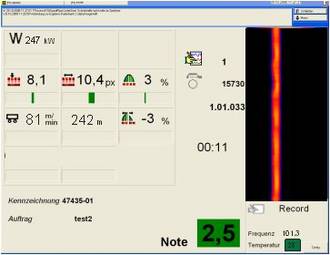

Image on the left: work monitor of the monitoring system

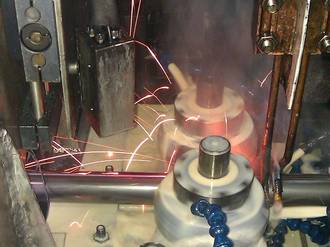

WeldQAS during the thermal field measurement

Application examples of seamless pipe production

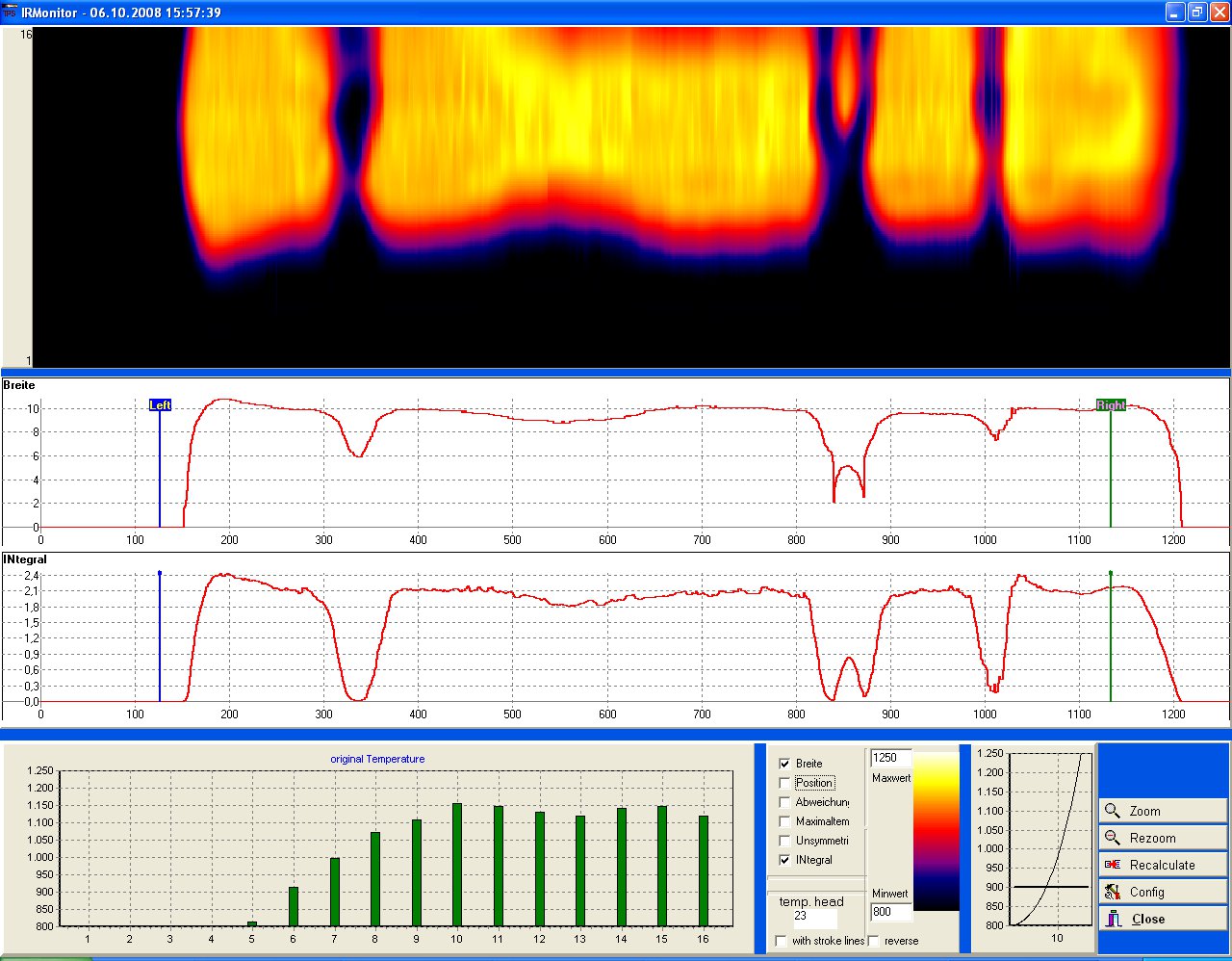

Each measurement generates a temperature profile perpendicular to the seam; a thermal pattern is generated due to the welding movement.

The measurement of these temperatures allows drawing conclusions for

the thermal conduction in the workpiece. Surface effects (weld penetration grooves, position of welding seam, open pores, holes, etc.) as well as internal effects such as root formation, weld penetration depth, symmetry of weld penetration are identified.

Digitalised thermal profiles are sent to the WeldQAS device for this purpose. Every profile is evaluated, saved, displayed and monitored here.

Characteristic values such as symmetry, width of a thermal zone, maximum temperature, etc. are determined from each thermal profile. Desired values that have been experienced in the past or the values that have been set and tolerances are compared simultaneously.

On exceeding tolerance limits, warning signals are triggered, defective points can be marked and the welding process can be stopped.

Thermal patterns and the characteristics derived from them are saved in WeldQAs and they can be allocated to welding seams.

- For all welding processes for steel/stainless steel and for accessing cooling welding seams

- High frequency induction welding, MAG, TIG, plasma, laser, etc.welding speed of up to 180 m/min

- Permanent use in a severely contaminated environment (welding vapours, weld spatter, water vapour, etc.) is possible due to:

- Glassless construction

- Gas purging and cross jet

- Non-stick technology against weld spatter

- Integrated water cooling

- Self-cleaning lens

corresponding to the usage areas for:

TIG process (standard equipment) Laser welding

Equipped with a focus lens and an optical filter

High frequency induction welding

Equipped with an additional protection housing and a special hose packet protection

MIG/MAG process

Robot-compatible wiring, special protection housing, self-cleaning lens

The TPS measuring head is installed in the welding direction behind the welding point, using a bracket. It is permanently connected with the supply unit through a hose packet that is installed further away from the immediate welding zone (3 m hose packet).

A digital connection is used to send the measurement data to the WeldQAS device where it is evaluated and stored.

Dimensions of the TPS power supply unit: L= 180 mm x B = 150 mm x H = 60 mm (without plug)

Weight of the TPS power supply unit: Approximately 1.5 kg

Weight of the TPS measuring head: Approximately 300 g (without cable and installation eyes)

Permissible welding speeds: Up to 180 m/min

Scanning frequency: 100, 200, 400 profiles per second

Working distance: Up to 200 mm

Recordable temperature range: 650 to 1350 °C

Resolution: 0.9 mm (0.6 mm)

Recordable seam width: Up to 21 mm

Operating temperature of the TPS power supply unit: 0 to 70 °C

Operating temperature of the TPS measuring head: Temperatures arising at the welding head (water cooling is a prerequisite)

TIG/plasma, HF compatibility: Yes