HKS offers measurement value sensors for all relevant welding processes. These calibrated sensors enable the use of welding technology in every welding system irrespective of the manufacturer.

Sensors are characterised by their high robustness. They can also be used under the most extreme conditions (high-voltage ignition for TIG welding)

due to intelligent protection circuits and a logical galvanic separation.

Depending on the process variables, you can select:

- Current / voltage

- Gas flow rate

- Wire feed speed

- Other process variables

Current and voltage are measured based on the principle of a compensated hall sensor. They can be used from standard measurements to comparison measurements for calibrating the display devices of welding systems used (device calibration)

Connection capability for HKS gas and wire sensors

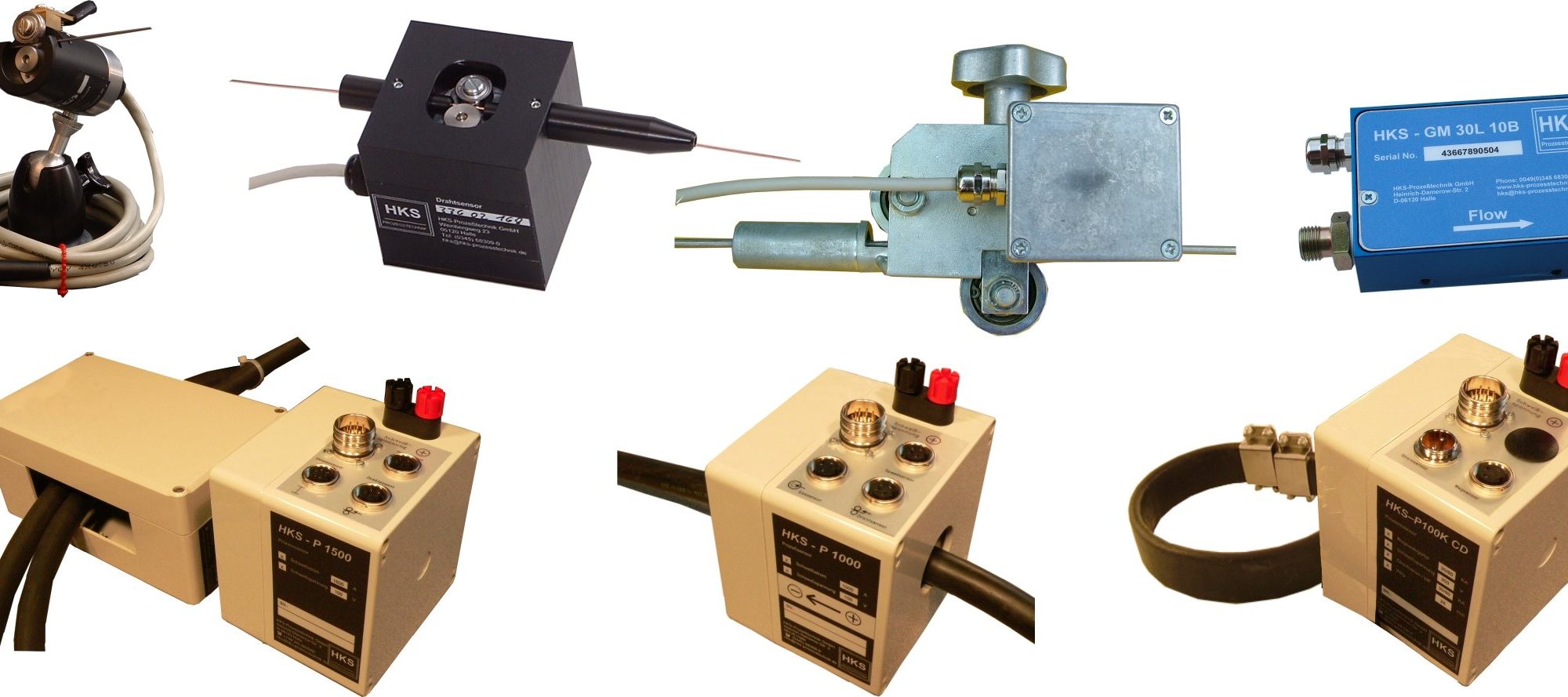

Process sensor P1000-S3

For all arc welding processes; Fully compatible with TIG / plasma

Measuring ranges:

Current: +/- 300 A; +/- 500 A; +/-1000 A

Voltage: +/- 100 V

Power supply: 9 - 36 V

Output: +/- 10 V

Accuracy: +/- 1%

Bandwidth:

- current 100 kHz

- voltage 20 kHz /100 kHz at optional "fast version"

Dimensions/weight: 120 x 120 x 105 mm, 1 kg

Process sensor P1500-S3

For submerged arc welding process

Measuring range: Current +/- 2000 A, (+/- 3000 A on request) Voltage +/- 100 V Power supply: 9...36 V

Output: +/- 10 V

Accuracy: +/- 2%

Bandwidth:

- current: 10 kHz

- voltage: 20 kHz /100 kHz at optional "fast version"

Dimensions/weight: Sensor 120 x 120 x 105 mm; 1 kg Mains transformer 120 x 200 x 90 mm; 1 kg

Please Note:

The P100K-H was especially develloped for the usage with our WeldQAS, WeldAnalyst or WeldScanner. Only these devices can reproduce correctly the high sampling rates.

Proces sensor P100K-H-S3

for resistance welding and stud welding (CD)

effective range:

current +/-20, 30, 60, 100 kA , drift DC/MF<1% full scale

voltage: +/- 10 V or 300V

supply: 9...36 V (3 W)

output: +/-10 V

bandwidth: U: 100 kHz; I: 10 kHz

accuracy: U: +/- 1,0 % v.MBE; I: +/- 1,5 % v.MBE

dimensions

LxWxH: 60x200x120 mm; weight: 0,7 kg

Rogowski-coil: diameter 120mm; weight: 0,5 kg

alignment:

Rogowski-coil

The gas flow rate is measured based on the principle of cooling of a heated sensor element that is exposed to the gas stream. It can be used for all non-combustible gases used in welding and cutting technology.

Connection option on HKS process sensors P1000 and P1500

Gas sensor GM 30L 10B -S3

Measuring range: 0 to 30 l/min, Ar

Inlet pressure: 10 bar

Power supply: 10...24 V DC, ca.70 mA

Output: 0 to 5 V

Accuracy: +/- 3%

Dimensions/weight: 98 x 65 x 28 mm; 0.5 kg

The wire speed is scanned through a roller mechanism using a pulse encoder for the wire diameter from 0.8 to 5 mm depending on the type.

Connection option on HKS process sensors P1000 and P1500

stationary wire sensor DV25ST-S3

(for permanent industrial use)

Optional: Analogue output

Measuring range: 0 to 25 m / min

Wire diameter: 0.8 to 2 mm

Power supply: 10 to 30 V

Output: 732 Hz at 5 m/min 3660 Hz at 25 m/min

Accuracy: 1%

Dimensions/weight: 60 x 60 x 50 mm; 300 g

Fastening: Clamping mandrel

Installation: directly on the wire feed box

Mobile wire sensor - DV25M-S3

(for overview measurements and laboratory use)

Optional: use for TIG

Measuring range: 0 to 25 m / min

Wire diameter: 0.8 to 2 mm

Power supply: 10 to 30 V

Output: 732 Hz at 5 m/min 3660 Hz at 25 m/min

Accuracy: 1%

Dimensions/weight: 85 x 60 x 35 mm; 465 g

Fastening: Magnetic foot

Installation: Clamp connection for the welding wire

wire sensor for submerged welding DV25UP-S3

(for permanent industrial use)

Measuring range: 0 to 25 m / min

Wire diameter: 2 to 6 mm

Power supply: 10 to 30 V

Output: 303 Hz at 5 m/min 1515 Hz at 25 m/min

Accuracy: 1%

Dimensions/weight: 170 x 120 x 70 mm; 960 g

Fastening: Clamping mandrel

Installation: instead of the target rate

Welding speed

Sensor for measuring the welding speed

Force

Sensor for measuring the pressure force during resistance welding

Distance

sensors for measuring the dipping depth in case of stud and resistance welding

Temperature

Temperature measurement (thermocell) and contactless measurement (pyrometer) for metal surfaces while welding, e.g. for measuring the cooling time

many other measurable process parameters. e.g.:

- preheating tempearature

- powder temperature

- acoustic emission

- coolant flow

- contact pressure