A measuring device for analysing welding processes

Quick decisions by the Production Department are decisive for competition. A continuous analysis of welding processes used, therefore forms a successful base.

WeldAnalyst is a reliable system used by expert welders in their daily operations as far as process and technology are concerned.

This system has proven its worth as the basic measuring technology for welding processes in theory and research.

The new WeldAnalyst-S3 is equipped with an ultra-high speed measurement mode. This means that sampling rates of up to 1 MHz can be achieved.

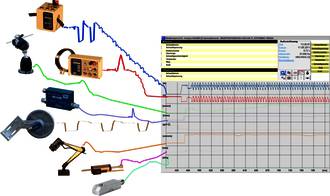

Modular system S3 for use in research and developement

The modular system consists of a "WeldAnalyst-S3 box", an industrial laptop and the corresponding sensors of the series S3. Up to 12 analog signals can be connected. (picture)

Compact system S3 for use in the production

(picture)

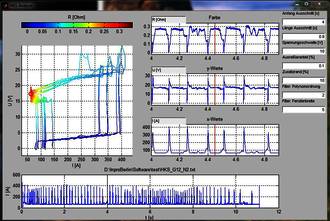

Time progressions of welding processes are highly dynamic. WeldAnalyst is a modern measuring device for complex dynamic analyses of all welding processes.

The new device generation with an integrated signal processor enables even better highly dynamic analyses of welding processes.

The base measuring system allows measuring up to 8 analogue signals and 4 counter inputs for recording the speeds directly.

An extensive range of measurement value encoders (sensors) for welding technology can be directly connected.

Each parameter is scanned up to 100.000 times per second.

Analysis tools, which have been specially optimised for welding, determine specific static and dynamic process characteristic values for every welding technology.

In addition to average and effective values of process parameters, dynamic characteristic values such as pulse frequencies, pulse widths, base current and pulse current for MIG/Mag pulse welding and many other parameters are calculated.

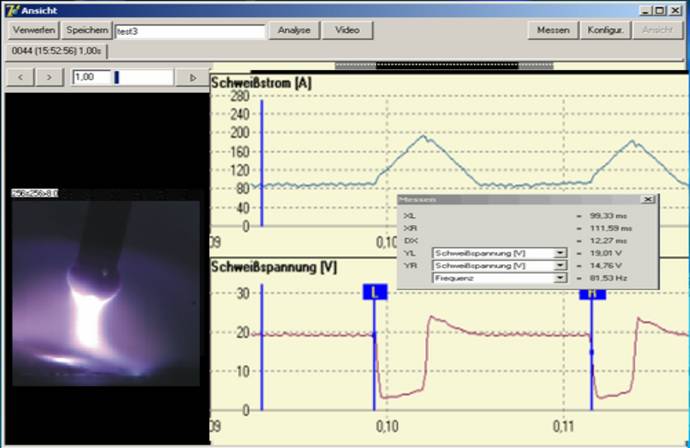

The synchronisation of recorded parameters with the video data of modern high-speed cameras is another area of application of WeldAnalyst. It supports many latest HS cameras by different manufacturers.

After completing measurements, the video data can be synchronously analysed with the recorded data in the camera memory. A time-consuming data transfer to a PC is not yet required at this point. Relevant areas can be cropped and saved in WeldAnalyst. The video data is transferred to WeldAnalyst only when it is saved.

The data is shown on the display as 100% synchronised and is saved synchronously.

It is saved in an avi format; the data can then be analysed in WeldAnalyst and in any other player software.

High-speed video short electric arc

High-speed video with synchronised current and voltage progressions of a short electric arc welding process

Camera: Photron SA3 SW

High-speed video with synchronised current and voltage progressions of a pulse welding process

Camera: Photron SA5 C