In the field of welding technology research, WeldAnalyst has proven itself as a measuring system for welding processes in theory and research.

The universal character in particular of the system in combination with different measuring sensors for all welding processes, has enabled its usage in the training of students and welding experts as well as in fundamental research.

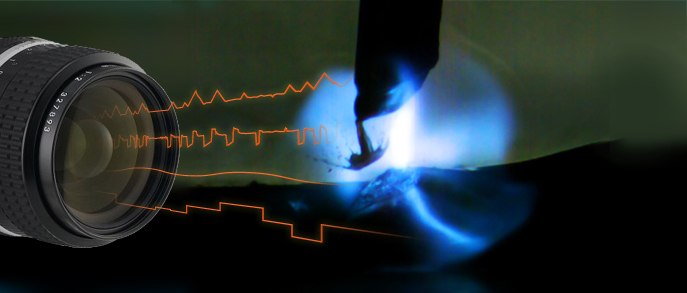

WeldAnalyst can be operated using different high-speed cameras and process parameters can be evaluated synchronously with the video. WeldAnalyst is thus suitable for examining the fundamental physical electric arc phenomena.

Extensive welding test series are optimally supported by the integrated test management module.

References:

- SLV Halle

- SLV Munich

- SLV Duisburg

- SLV Hanover

- IfW Jena

- Welding institutes in France, Japan, China, Netherlands, Romania, Poland, Finland

- Uni Magdeburg

- Uni Chemnitz

- Uni Aachen

- BAM Berlin

- Uni Stuttgart

WeldAnalyst is used in many measuring projects for welding technology-based development and device optimisation. The coupling with modern high-speed cameras especially enables evaluating the welding process.

When developing torches, high-speed recordings with a streak-like lens in combination with synchronous parameter display are used.

Another area of application includes long-term measurements across several hours with complete documentation of all welding parameters as well as additional temperatures for load tests for welding torches and welding devices.

Different applications for electric arc and resistance welding with and without a high-speed camera have been implemented.

In additional to long-term tests associated with series production, HKS measuring systems are frequently used for process optimisation and testing new welding technologies.

References:

- Audi

- BMW

- Daimler

- Nissan

- Volkswagen

Requirements for a complete welding documentation are often in the foreground in the field of aviation and space travel

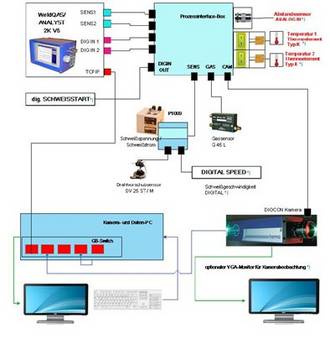

All process parameters can be recorded and dynamic characteristic values can be calculated and evaluated synchronously with video streaming of a monitoring camera. The welding process may take several hours and is fully documented.

Example of application: Process documentation

Process parameters:

- Welding current

- Welding voltage

- Gas flow rate

- Wire feed

- Torch distance

- Temperatures

- Welding speed

Dynamic parameters:

- AC pulse frequency

- Pulse current

- Base current

- Pulse frequency

- Pulse width

- Video recording of process at 80 fps

Different applications for electric arc welding with and without a high-speed camera have been implemented.

Solutions with up to 5 welding torches for special submerged arc welding processes or support for extensive welding test series are only a few examples from this field.

References:

- TATA Steel

- Salzgitter

- Arcelor Mittal

- Outokumpu

- Avesta

- Thyssen Steel

Force measurement for spot welding using FaserBragg sensors

Faser-Bragg-Gitter sensors (FBGS) in the form of an expansion sensor design that has been developed at the Günter-Köhler-Institut für Fügetechnik und Werkstoffprüfung (institute for joining technology and material testing) (ifw) in Jena provide an alternative for measuring the force for resistance spot welding. This sensor design is tested in cooperation with an industrial customer.

Measurement values are processed in WeldAnalyst. Comparative examinations using conventional force sensors confirm the higher measurement dynamics and accuracy.

Wire measurement using a dynamically-moved wire (CMT process)

A standard wire sensor was used in a special measurement assembly in cooperation with an industrial partner. This sensor allows recording the wire feed speed of welding processes with wire electrodes moved forward and backward (e.g. CMT process).

Contactless wire feed measurements using PIV

The contactless measurement of a moving wire electrode when welding through a pattern tracking on the moving wire electrode using high-speed-particle-image-velocimetry (PIV) is an alternative to the high-precision measurement of the wire feed. A high-speed camera records the moving wire electrode. Software for pattern tracking (PIV) has been developed in cooperation with the Martin Luther University, Halle. It identifies the smallest patterns on the wire and calculates the wire feed speed using these patterns.